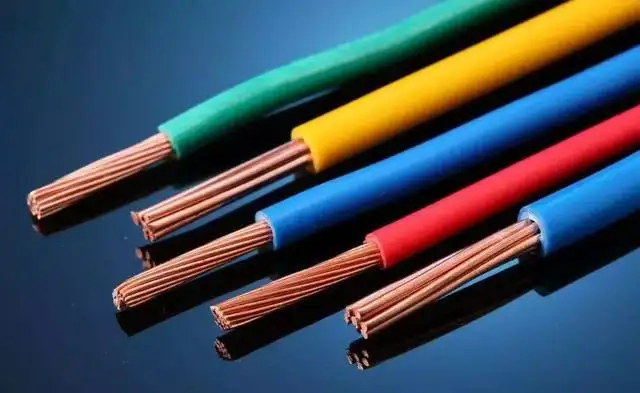

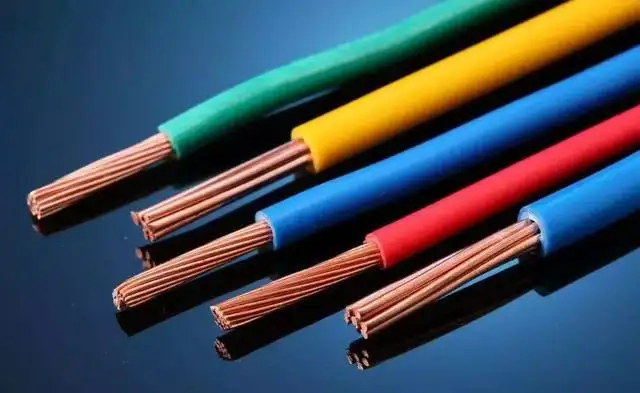

We know that now life is inseparable from electricity, of course, it is inseparable from wire and cable, due to the different use of different occasions for the selection of wire and cable is also different, high voltage cable, frequency conversion cable, flame retardant cable, etc., these different characteristics of the cable application site is different. Wire and cable manufacturing industry is a material finishing and assembly industry.

First, the amount of material is huge, and the material cost in cable products accounts for 80-90% of the total manufacturing cost;

Second, there are many types and varieties of materials used, and the performance requirements are particularly high, such as conductor copper, which requires the purity of copper to be above 99.95%, and some products should use oxygen-free high-purity copper;

Third, the selection of materials will have a decisive impact on the manufacturing process, product performance and service life.

Wire and cable materials for the selection of copper wire is particularly important, if a little careless may cause safety accidents, so it is very important to understand some wire and cable copper wire related problems. Tianxing cable gives you some of the reasons for yellow copper wire and treatment methods!

Common causes of yellow copper wire

1, the tin furnace temperature is too high, the fluidity is large, resulting in the coating pinhole is too large, copper tin penetration is fast

2, tin layer is too thin, copper tin penetration fast

3, the flux halogen residue is too much, the copper surface pickling is not thorough enough

4, the packaging time is too fast, the heat is not dispersed, and the impurities in the tin furnace are too much

5. Copper quality is not up to standard, too many impurities

6. The temperature has an effect on the activity of copper atoms, and the hot day yellows faster than the cold day

Treatment method

1. Mold diameter > line length +0.02mm(the purpose is very simple not too thin coating);

2. After production, it can be placed for about 2 hours before packaging (purpose: internal heat dissipation)

3. Buy a good flux and match the flux concentration, mainly because the flux affects the tinning quality;

4. Choose better oxygen-free copper wire and regular manufacturers' products.

The above is the reason and treatment method of the yellow copper wire in the wire and cable summarized by Tianxing cable. I hope you know more about the knowledge of wire and cable. At the same time, I hope I can help you.

Qingdao Tianxing Cable Co., Ltd. specializes in the production of customized wire and cable manufacturers, exports to more than 40 countries and regions around the world, the annual production capacity of 1 billion yuan. 6000 square meters of storage, standing hundreds of millions of inventory, order demand for rapid distribution and delivery, large prices more favorable. Hotline: 16678668098